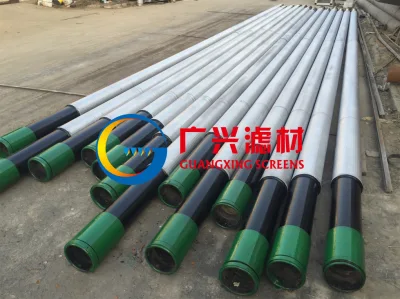

Oil Well Pipe Base Screen 4 1 / 2 ′′ N80 with Slot 10

Basic Info

| Model NO. | 219 |

| Transport Package | Wooden |

| Specification | 177.8, 244.5 |

| Trademark | Guangxing |

| Origin | China |

| HS Code | 8421999090 |

| Production Capacity | 3000m |

Product Description

HENGSHUI GUANGXING SCREENS CO.,LTDAdd:No.2589 West Shengli Road ,Hengshui,Hebei,ChinaPostalcode :053000Company Introduction: Hengshui guangxing screens co.,ltd founded in 1986,is a major manufacture and supplier of stainless steel filtration products for professional end-users in the world.It is equipped with modern machines and latest technology for the manufacture of high quality welded wedge wire screens in various shapes and size .Manufacturer Of All Welded Wire Wrapped Self-Cleaning Wedge Wire Screen. Specializing In Down-Hole Sand Control For Water, Environmental, Oil & Gas Wells. Size Range From 3/4" To 36" Diameter. Rod Base Screens, Pipe Base Screens, & Pre Pack Screens Available .Now our products have been sold to many countries,such as North America ,Europe ,The Middle East etc.Because we depend on not the rests with our products and service,but also with the skill of our staff,the technical knoweledge and over 20 years of experience in the field.We have been recongnized for our excellence in customer solutions creativity flexibility and no nonsense mentality coupled with short delivery time and competitive price.Pre-packed screen provide excellence service of sand control in oil, gas and water wells for its unique construction. Pre-packed screen is a modification of pipe based wire wrapped screen. Its addition of a modular gravel pack makes it especially suitable for sand control where conventional gravel packing fails.Available in oil and gas well completions, especially in an open or cased hole with unconsolidated formations where stand-alone screen is needed.Pre-packed screen is easy to install for its unique construction.Stainless steel material gives it ability of resisting erosion.Pre-packed screen is equipped with packed layer itself. This unique configuration eliminates gravel placement and significantly shorten the time of drilling a well.Stronger construction like support rods reduces maintenance costs.Pre-packed screen is quite affordable in contrast to slotted liner.Features self-cleaning and anti-plugging.Pre-packed screen vertical view and side viewConstruction:Pre-packed screen is comprised of six parts (from outer to inner) - outer screen, outer support rod, pre-packed gravel, inner screen, inner support rods and base pipe. This is a typical model of dual-screen prepack which features double wire wrapped screens. The perforated base pipe is covered by inner wire wrapped jacket, whose diameter is smaller than the outer jacket. Between the two layers of jackets, an annular void is packed with silica sand with the appropriate size. The sand is coated by resin or ceramic beads. The gauge of the jacket wire is determined by the packed sand, while the size of the sand is determined by the formulation particle size distribution.Materials:Pre-packed screens can be fabricated in stainless steel 304, 316L, low carbon steel or other special alloys like Monel 400. Materials are available for specific alloy as required.Stainless steel 304 of Pipe sand control wire wrapped Screen filters for deep water well drilling:

Slip on wedge wire screen consists of a perforated LCS base pipe and an outer stainless steel jacket slipped on it.Outer jacket is made of V-shaped profile wire, which is spirally wrapped around support rods welded in each intersectingpoint.Wedge wire screen offers continuous slot openings providing high open area, as well as accurate slot dimension.

Materials: stainless steel wire AISI 304, 316L,

Benefits:

Certified slot accuracy along entire screen length;

Superior open area due to their continuous slot openings;

Keystone slot design for the maximum flow, better self-cleaning and minimum plugging;

Wide range of standard configurations;

Withstands high-pressure and high-temperature conditions;

A uniform and efficient well development due to long-term sand control;

Significantly reduce potential damage of surface equipment and subsequent maintenance costs

Pipe based sand control screen:

Specfications:

Slot size: 0.05,0.1,0.15,0.2,0.25,0.3,0.5 to 20mm also achieved upon request.

Material: Low-carbon steel,medium carbon steel,stainless steel (304,304L,316,316L,duplex stainless steel,2205,2207)

Length: 30mm to 6000mm

Outer Diameter: 73mm to 600mm

Wedge Wire Specifications:0.75X1.5mm,1X2mm,1.5X2.5mm,2X3mm,2.3X4mm,3X5mm,3.5X6.5mm

End connection: Plain beveled ends, flanged or threaded couplings

Application:

Heavy oil, sand oil, SAGD, CBM, bitumen.

Water injection.

Horizontal, vertical, deviated oil and gas, water wells.

Stand-alone operations, cased hole, open hole environments and horizontal completions.

Packing:

Standard international package for the stainless steel well screens plate for oil filter

1. Wood package to keep the goods without the wet from the sea and the collision in the container

2. Plastics package:

Cheaper than the wood package and save more space for the goods load.

3. Woods pieces package:

Stronger than the plastic package, and cheaper than the wood package,

The best choose for the filters.